ACY Yarn (English abbreviation of Air Covered yarn) is a textured polyester yarn coated in Spandex or similar elastic yarns and used in the production of fabrics like pantyhose, seamless underwear and seamless knit fabrics. Fabric made from this type of yarn features softness with good stretch, great hand feel, color retention as well as high strength, tensile modulus and elongation properties - which makes these durable enough to use again and again for many different projects.

Textured yarns are covered with spandex or similar elastic fibers for maximum stretch, bounce, and resilience, then coated with polyester to provide a smooth surface. These types of yarns are highly popular because they respond well to pre-shrink washing for a comfortable yet smooth feel, as well as being extremely durable, standing up well against repeated usage in daily life.

At its core lies an assembly process in which spandex fibers are wrapped around the sheath of textured yarn before being drawn through a nozzle with compressed air to produce an outer covering for it. As compressed air compresses both layers together, interlacing creates a composite yarn product without twists.

Fancy yarns are textured polyester and nylon yarns that incorporate various textures, colors, effects and other features to give fabric they are used in an original appearance. Fancy yarns are created during the spinning process and can be used either alone or combined with base and luster yarns; adding color creates mottled effects while mixing luster and matte yarns produces marbleized effects.

These yarns are created by texturising partially or fully-oriented polyester multifilament yarn to produce desired characteristics, depending on the texturing method employed, these may include soft or hard crimp, low bulk, high or low tensile modulus/elongation and soft or hard crimp depending on desired texture, as well as quality control measures to maintain dyeability, tenacity/bulk, elongation etc. They're commonly found used in outer/inner garments and skin-clinging fabrics; manufactured using modern high speed draw texturising machines equipped with stringent quality control measures in regards to dye ability/tenacity/bulkness/elongation/tenacy/tenacity and/or/elongation standards to maintain desired characteristics such as dye ability/tenac/bulkness as well as tight quality control regarding dye ability/tenacity/bulkness/elongation etc.

Crimped or coiled fibers can be produced through various processes: being heated up quickly before cooling down quickly; applying false twists on filaments before untwisting to create the coiling effect, or using a device called a "crimper." Crimping leaves fibers thick but allows them to still be stretched and relaxed without breaking.

Crimped yarns are among the simplest of all yarn types and can be produced using natural or synthetic fibers. Cotton, wool and synthetic blends that have been heat set before being crimped by machine or by hand are among the most frequently produced crimped yarns; using either a ring crimper or by inserting slack into fiber and stretching it are typically employed for this process.

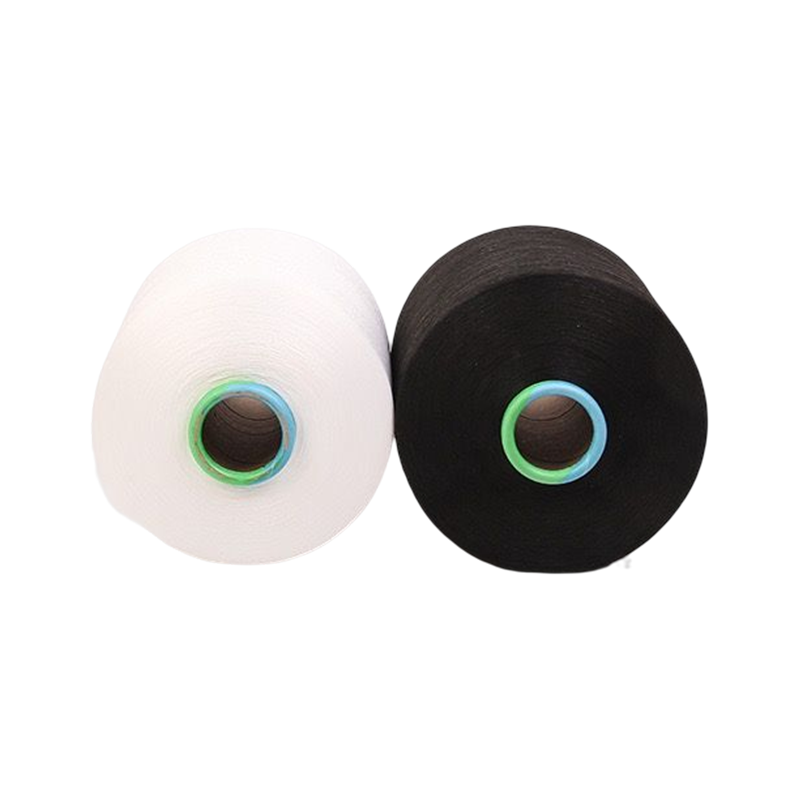

ACY Yarn

English

English

Español

Español

-2.png)

-2.png)

-3.png)